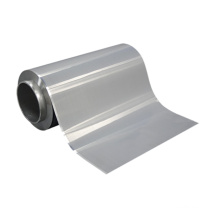

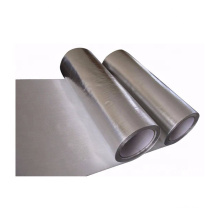

4% Thoriated Tungsten Wire in Coil in Stock

4% Thoriated Tungsten Wire in Coil in Stock

| Payment Type: | L/C, T/T, Paypal, Money Gram, Western Union |

|---|---|

| Min. Order: | 5 |

| Productivity: | 100 Tons Per Month |

|---|---|

| Place of Origin: | Baoji, Shaanxi |

| Supply Ability: | 100 Tons Per Month |

Basic Info

Model No.: purity

Product Description

Model NO.: purity Purity: W≥99.95% Supply State: Sintering or Processing Trademark: Huaheng Origin: Baoji, Shaanxi Type: Tungsten Wire Appearance: Silver Gray Metal Luster Quality Standard: According to Customer Specification: ISO 9001: 2008 HS Code: 810890 4% Thoriated Tungsten Wire in Coil in Stock

Specification

Dimensions and Tolerance

Unit:mm

8 Production process:

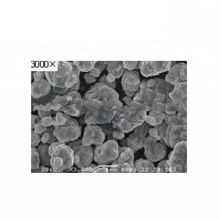

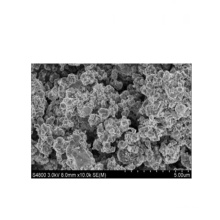

raw Materials (tungsten powder) --- isostatic pressing --- mechanical processing - --IF induction sintering --- mechanical processing-detection check--- tungsten cruciblesSpecial sizes can be manufactured based on customers' requirements.

9 Production equipments: CNC vertical turning machine, CNC milling machine, wire cutting machine

10 Application:

Since the melting point of tungsten has reached 3410ºC, tungsten crucible is widely applied in industry

furnace such as sapphire growth furnace, quartz glass melting furnace, and rare earth smelting furnace.

The temperature in working environment of tungsten crucible is above 2000ºC.

For sapphire crystal growth furnace, high-purity, high- density, no internal-crack tungsten crucible with

Other features of exact measurement and smooth surface has decisive influence on success ratio of

seed growth, quality control of pulling crystal, metamictization pot-committed and service life during

sapphire growth process, and we are willing to be checked by professional units.

If you need more information, please contact us.

11 Packaging

First packaging with moisture-proof paper;

Second packaging with kraft paper;

Third packaging with foam plastics in All side of plywood case;

Finally packing products in plywood case.

Or as your request.

12 .Transportation

Shipping goods by TNT, DHL, Fedex, UPS, EMS etc. or by air or by sea depends on the purchasing quantity.

13 Payment

We accept T/T, L/C, Paypal, Western Union etc which can be negotiated and depends on the order.

14. Why Choose Us

Premium Quality

All the products are mill certified and 100% traceable from mill processing through melt source to maintain quality control requirements. Third Party Inspectation.

Competitive Price

Working from titanium sponge and finishing the raw material melting, milling, drawing, cutting, packaging in house for most products, this makes our prices much more competitive as the middleman is cut out. And our cooperated forwarder and courier charge us reasonable costs for goods delivery.

Superior Service and After-Service

Quick response and on-time delivery. We also offer value-added processing such as welding, drilling, surface treatment and customized cutting.

Kindly you please contact with me, If you're interested in our products.

Contact Information:

Name: Susan

Mobile: +86-187 92 96 00 59

Web: www.chinahhmetal.com Contact us if you need more details on Tungsten Wire. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tungsten Bar、Tungsten Rod. If these products fail to match your need, please contact us and we would like to provide relevant information.

Specification

| Item name | Tungsten Bar/Rod | |

| Purity | W Purity: 99.95% | |

| Density | W1,W2,WAL1,WAL2,W-Ni-Fe, W-Ni-Cu, WMO50,WMO20 | |

| Density | 1.Sintering tungsten crucible Density: 18.0 - 18.5 g/cm3 2.Forging tungsten crucible Density: 18.5 - 19.1 g/cm3 | |

| Dimension & Cubage | According to your needs or drawings | |

| Delivery time | 7-15 days | |

| Application | 1.smelting of rare earth metals 2.heating elements of induction furnace 3. solar energy and sapphire. | |

| Technique (Type) | Sintering, stamping, spinning. | |

| Working temperature | 1800 - 2600 DC | |

| Special sizes can be manufactured based on customers' requirements. | ||

Dimensions and Tolerance

| Supply Situation | Dimensions | Tolerance | ||

| Diameter(mm) | Height(mm) | Diameter(mm) | Height(mm) | |

| Sintering | 10-500 | 10-750 | ±5 | ±5 |

| Forging | 10-100 | 10-120 | ±1 | ±2 |

| Sintering and Machining | 100-550 | 10-700 | ±0.5 | ±1 |

Unit:mm

| Diameter(mm) | Thickness(mm) | Height(mm) | Surface finish | Inner surface finish | Inner bottom finish |

| 30 ~ 50 | 2 ~ 10 | ≤500 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 50 ~ 100 | 3 ~ 15 | ≤1000 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 100 ~ 150 | 3 ~ 15 | ≤1000 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 150 ~ 200 | 5 ~ 20 | ≤1000 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 200 ~ 300 | 8 ~ 20 | ≤1000 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 300 ~ 400 | 8 ~ 30 | ≤1000 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 400 ~ 450 | 8 ~ 30 | ≤1000 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

| 450 ~ 600 | 8 ~ 30 | ≤1000 | ≤Ra2.0 | ≤Ra2.4 | ≤Ra2.8 |

8 Production process:

raw Materials (tungsten powder) --- isostatic pressing --- mechanical processing - --IF induction sintering --- mechanical processing-detection check--- tungsten cruciblesSpecial sizes can be manufactured based on customers' requirements.

9 Production equipments: CNC vertical turning machine, CNC milling machine, wire cutting machine

10 Application:

Since the melting point of tungsten has reached 3410ºC, tungsten crucible is widely applied in industry

furnace such as sapphire growth furnace, quartz glass melting furnace, and rare earth smelting furnace.

The temperature in working environment of tungsten crucible is above 2000ºC.

For sapphire crystal growth furnace, high-purity, high- density, no internal-crack tungsten crucible with

Other features of exact measurement and smooth surface has decisive influence on success ratio of

seed growth, quality control of pulling crystal, metamictization pot-committed and service life during

sapphire growth process, and we are willing to be checked by professional units.

If you need more information, please contact us.

11 Packaging

First packaging with moisture-proof paper;

Second packaging with kraft paper;

Third packaging with foam plastics in All side of plywood case;

Finally packing products in plywood case.

Or as your request.

12 .Transportation

Shipping goods by TNT, DHL, Fedex, UPS, EMS etc. or by air or by sea depends on the purchasing quantity.

13 Payment

We accept T/T, L/C, Paypal, Western Union etc which can be negotiated and depends on the order.

14. Why Choose Us

Premium Quality

All the products are mill certified and 100% traceable from mill processing through melt source to maintain quality control requirements. Third Party Inspectation.

Competitive Price

Working from titanium sponge and finishing the raw material melting, milling, drawing, cutting, packaging in house for most products, this makes our prices much more competitive as the middleman is cut out. And our cooperated forwarder and courier charge us reasonable costs for goods delivery.

Superior Service and After-Service

Quick response and on-time delivery. We also offer value-added processing such as welding, drilling, surface treatment and customized cutting.

Kindly you please contact with me, If you're interested in our products.

Contact Information:

Name: Susan

Mobile: +86-187 92 96 00 59

Web: www.chinahhmetal.com Contact us if you need more details on Tungsten Wire. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tungsten Bar、Tungsten Rod. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Molybdenum Electrode

Other Products

Hot Products

Titanium Nail for Smoking Gr2 Domeless in ChinaZr702 Zirconium Bar Used for IndustrialMmo Titanium Anode for Swimming PoolPlatinized Pure Titanium Mesh for Electrolytic DepositionGr1 Gr2 Titanium Sputtering Target for PVD CoatingGr5 Titanium Hex Flange Bolts with Best PriceHigh Quality ASTM B348 Gr1 Titanium Rod with Best PriceASTM B348 Gr2 Titanium Flat Bars with Best PriceGr 2 Cp Titanium Wire in Stock with Best PriceBaoji Gr 2 Titanium Plate/Sheet for Industry29er Titanium Mountain Bike Frame with Best PriceGrade 2 Titanium Elbow with Good Quality in ChinaGr5 ASTM B863 Titanium Wire with Best PriceBright and Smooth Surface Pure Titanium PlateTitanium & Titanium Alloy Foils in CoilsHot Sell Titanium Strips/Foils for Coating